The Stapp EBC can be used with fixed and moving targets in order to accommodate today’s leading edge live fire training. The angled EBC bed or “Safety fitting” is built on a support surface of recycled and resource-friendly materials and does not require sectional dividers.

STAPP EBC performs best when fired upon with lead bullets and full metal jacket projectiles for firearms, safely handling any calibre up to 12 mm in diameter. Other types of projectiles can also be captured by the STAPP EBC, but some modifications or additional maintenance will be necessary to accommodate other rounds.

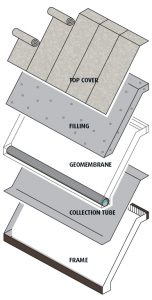

The spent projectiles and contaminates are fully collected safely in the STAPP EBC safety fitting – which is also ricochet proof even at extreme cold temperatures. Hence, all harmful materials and bullets are contained therein, safely awaiting periodic removal and recycling.

STAPP EBC can be built in a straight line or curved, and without limitation in the height and length. Current targets can be used as safety fitting without limiting section rings. The STAPP EBC is designed primarily for outdoor use but can be adapted easily for indoor use.

CONSTRUCTION

The standard STAPP EBC can be installed and made fully operational anywhere in the world, in any environment in about one week.

The patented STAPP RIKO-Plank is made of 100% recyclable plastic that is specifically created to cope with extreme temperatures and a full range of common ammunition types.

The STAPP RIKO-Plank is made from plastic derived from recycled materials and can be reused up to eight times before it has lost its properties. The plastic is approved for burning in thermal plants. The STAPP RIKO-Plank is completely maintenance-free.

The STAPP Safety Fitting Screen (SFC) is a cost-effective choice to replace the older site-built structures.

The STAPP SFC is comprised of a concrete module as dimensioned in view of the safety of shooting ranges and with the ability to dismantle and move. The elements clothed after installation with STAPP RIKO-plank at a distance studs. By choosing the STAPP SFC means that the STAPP EBC safety fitting can often be reduced significantly in height to accommodate tighter fitting installations, such as at an indoor range.

UNIQUE BENEFITS

Security

- Experiments show that STAPP EBC capable of handling more than 30,000 projectiles against a precision 60 x 60 cm target

- Even tracer rounds can be used safely with no risk of fire

- No risk of ricochets when rounds strike the safety fitting in any weather

Recycling

- The safety fitting is constructed of materials that are 100% recyclable and many of the materials are recycled and resource-friendly

- Collected bullets and fragments can be recycled

Financial

- STAPP EBC customers can create a reasonable revenue stream in the recycled metals market or, ammunition developers might be able to reduce materials costs by recycling bullet materials

- The existing legacy old safety fittings of gravel or restored ramparts of earth can serve as a base foundation for STAPP EBC. Hence, customers are able to increase their savings with the STAPP EBC system.

- Maintenance costs of STAPP EBC upkeep are lower.

Maintenance

- Maintenance can be handled by STAPP EBC or a customer’s own team can be personally trained by STAPP EBC experts to its own high proprietary standard.

- Projectiles are simply cleared from the filler “stop” material with mobile collection units.

- The stop material is cleaned and reused.

- The STAPP EBC cover prepared at the large number of holes through binding the same type of material with the rubber compound used during construction.

- The STAPP EBC is constructed of its own patented materials that have long shelf-life and unprecedented extended durability, outlasting competing materials by eight times as long before needing to be replaced.

- Once repaired to manufacturer specifications, the STAPP EBC continues to meet all approvals, ratings and guidelines for effectiveness, safety and environmental protection.

Approvals

- STAPP EBC is approved by the Swedish Armed Forces

- STAPP EBC has been studied, tested, rated and approved by for the U.S. EPA